Saving the world like a superhero; yes, you can! You might think that that’s a little crazy and far fetched. But as a refrigeration mechanic every repair you perform can prevent greenhouse emissions and slow global warming. And every new concept and idea on cooling can improve the way we live. So, go ahead and make a difference. Start saving the world one gas leak at a time.

Being a refrigeration/air conditioning technician is more than just being a hero. It’s a great trade. You get to meet great people, travel and earn awesome money (after the first 4 years that is). Refrigeration and air conditioning is made up from many different trades and covers many different areas. You can condition the air on an Airbus Dreamliner or keep the meat cold at your local supermarket. And your daily tasks can include things like programming electronic controls or welding new or busted pipes.

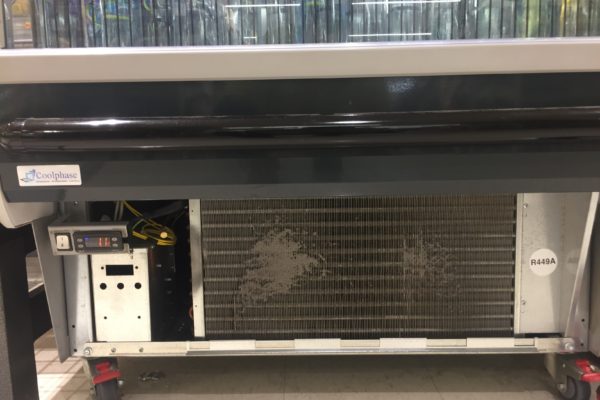

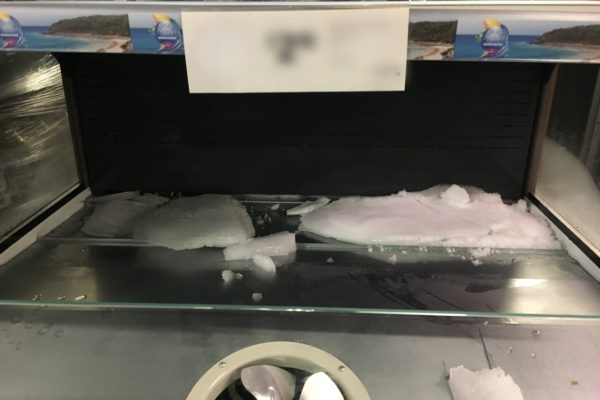

The majority of the work we do at Coolphase is on commercial refrigeration equipment. And one of the most interesting parts of our job right now is transitioning supermarkets to natural refrigerants. Yes, you guessed it, saving the world by reducing carbon footprints.

At Coolphase we give kids the opportunity to do something great every year. In 2022 we’ll again be employing two first year refrigeration apprentices and one electrical apprentice. Having a constant flow of trainees ensures that our business can meet our legendary requirements well into the future.

If you want to learn more, just give us a call. We are more than happy to provide any information you may need. Refrigeration is a great career. #livethechill